GRC GIANNUZZI RESEARCH CENTER

Giannuzzi Research Center is one of the few ENAC accredited testing laboratories since 2015. Born from a collaboration with Lecce University of Study, and with which is still in collaboration, GRC has focused and evolved in the aerospace industry. The main fields of development are mechanical and physical characterization of material, product, and process development. It is equipped with innovative technology such as 3D scanners for dimensional and geometrical control that permits to compare real models with original 3D models. There are 2 main research fields that are explored at the R&D Laboratory:

- Materials research (New materials research serves to develop new products and improve the performance of existing ones, making them competitive on the market)

- Process research (the research of new technologies of product development to optimize and improve the production process)

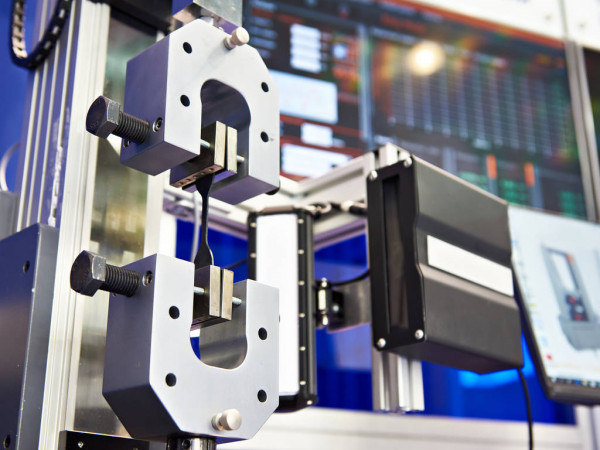

The Lab executes the Mechanical Characterization of materials, in accordance with International Standards ISO, ASTM, Client Standards and Test Procedures. The mechanical testing program includes:

- Tensile Test – Standard Test Method for Tensile Properties of Plastics

- T-Peel Test – Standard Test Method for Peel Resistance of Adhesives (T-Peel)

- Flexure Test – Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

- Flatwise Test – Flatwise Tensile Strength of Sandwich Constructions

- Bearing Test – Standard Test Method for Bearing Response of Polymer Matrix Composite Laminates

- Peel 180° Test – Standard Test Method for Peel or Stripping Strength of Adhesive Bonds

- Lap Shear Test – Standard Test Methods for Determining Strength of Adhesive Bonding Rigid Plastic Lap-Shear by Tension Loading

The Laboratory also executes the Flammability Vertical Test in accordance with FAR 25.853 requirements. The internal instrumentation allows you to perform the various tests at a specific temperature in the range of -100°C to +350°C